Industrial air hose reels and DIY models may look similar, but their purpose and performance differ in key ways. Industrial air hose reels use stronger materials, higher pressure ratings, and longer hose capacities to handle demanding, continuous use, while DIY models focus on convenience and light-duty tasks. This difference affects not only how each performs but also how long they last in real work environments.

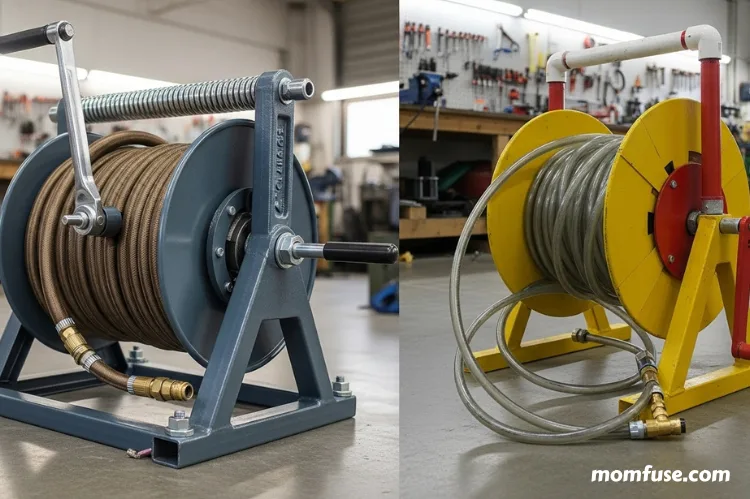

A closer look reveals that industrial reels often include steel frames, sealed bearings, and heavy-duty springs designed for constant operation. DIY models, on the other hand, use lighter materials that suit smaller garages or home projects. These design choices show how each type serves a different user and workload.

Understanding these differences helps anyone choose the right reel for their setup. The following sections explain what sets industrial reels apart, how to match a reel to specific tasks, and what features matter most for safety and efficiency.

Core Differences Between Industrial and DIY Air Hose Reels

Industrial air hose reels use stronger materials, higher pressure ratings, and safer retraction systems than DIY models. They also support larger hose capacities and offer more flexible mounting options suited to busy workshop layouts.

Construction and Durability

Industrial reels use steel or heavy-gauge aluminum frames that resist corrosion and physical stress. Their parts often include sealed bearings and powder-coated finishes for long-term use in demanding environments. These materials protect against moisture, dust, and impact damage.

DIY models usually rely on plastic or light metal housings. While lighter and easier to install, they wear faster under frequent use. Industrial models often qualify as an air hose reel with long-lasting protection because their build prevents rust and deformation over years of operation.

Industrial reels also feature reinforced brackets that distribute weight evenly. This design reduces the chance of frame bending or spring failure. In contrast, DIY reels may loosen or crack if mounted on weak surfaces or exposed to constant tension.

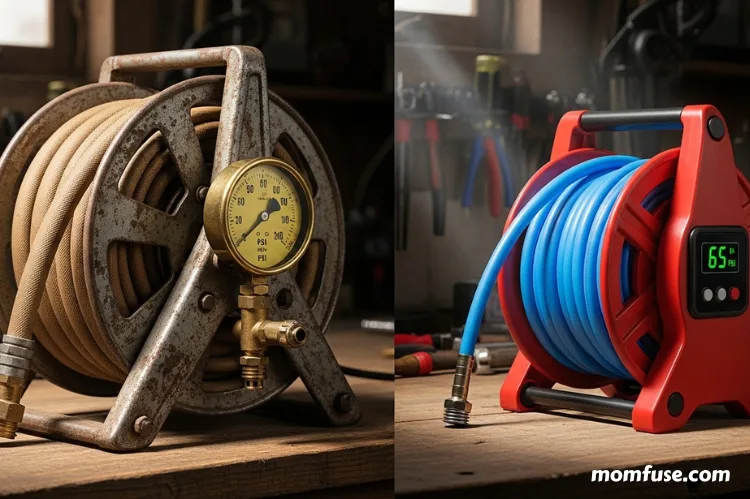

Pressure Ratings and Hose Capacity

Industrial air hose reels handle higher working pressures, often up to 300 PSI or more, which supports pneumatic tools in manufacturing or automotive repair. Their hoses can reach 50 to 100 feet without losing air pressure or flexibility.

DIY versions usually rate between 150 and 250 PSI and carry shorter hoses, typically under 50 feet. These limits suit small compressors used for inflating tires or powering light tools.

The difference in pressure rating directly affects performance. Industrial reels maintain consistent airflow through larger-diameter hoses, reducing tool lag. DIY units may show pressure drops over distance or during continuous use, which can interrupt work.

Retraction Mechanisms and Safety

Industrial reels use spring-driven or motor-assisted retraction systems that control hose movement smoothly. Many include adjustable stop mechanisms that lock the hose at specific lengths. This prevents sudden snap-back, which can damage fittings or injure users.

DIY reels often rely on simpler spring systems with less tension control. They retract faster but can whip the hose if released abruptly. Industrial models include enclosed springs that protect internal parts from dust and reduce maintenance needs.

Safety also improves through controlled retraction speed and consistent tension. These features keep hoses organized and prevent trip hazards, which is important in large workshops with multiple users.

Mounting Options and Workspace Integration

Industrial reels support wall, ceiling, or floor mounting, allowing flexible placement in tight or high-traffic areas. Their heavy frames require solid mounting surfaces but give stable operation once installed.

DIY units usually mount on walls with lighter brackets or portable bases. They work well in garages or small workspaces but may shift under heavy pull.

Industrial systems integrate better into organized layouts. Multi-position swivels let hoses move freely without twisting, improving workflow. Proper mounting also extends reel life by reducing strain on the hose and fittings, keeping the workspace safe and efficient.

Selecting the Right Air Hose Reel for Your Needs

Choosing the correct air hose reel depends on the type of work, operating environment, and the pneumatic tools in use. The right match improves air delivery, reduces wear, and keeps the workspace safe and organized.

Hose Material and Environmental Suitability

The hose material affects durability, flexibility, and performance under pressure. Rubber hoses handle high temperatures and heavy use but weigh more. PVC hoses cost less and resist abrasion, yet they can stiffen in cold weather. Hybrid hoses combine flexibility with moderate strength, making them suitable for mixed environments.

Temperature, humidity, and chemical exposure also influence material choice. A workshop with oil or solvents needs hoses with chemical-resistant coatings. Outdoor or unheated areas benefit from materials that remain flexible below freezing.

Industrial air hose reels often use steel or heavy-duty polymers to protect hoses from wear. In contrast, DIY models may use lighter materials that degrade faster under constant use. Selecting the right hose material prevents air leaks, cracking, and premature failure.

Hose Length and Diameter Considerations

Hose length determines reach, while diameter affects airflow and pressure. A 3/8-inch hose suits most pneumatic tools, whereas a 1/2-inch hose supports higher air volume for industrial equipment. Shorter hoses reduce pressure drop, but longer hoses provide a greater range for large workspaces.

A reel that holds 25 to 50 feet of hose fits small garages or hobby setups. Industrial shops often require 75 to 100 feet to reach multiple workstations. However, longer hoses add weight and may strain retraction systems if the reel lacks proper tension control.

Retractable air hose reels help manage longer hoses by keeping them stored neatly. A correct balance between hose length and diameter maintains steady airflow and minimizes tool performance issues.

Compatibility with Pneumatic Tools and Equipment

Each pneumatic tool has specific air volume and pressure needs. Impact wrenches, grinders, and sanders require a steady supply of compressed air, often at 90 PSI or higher. Matching the reel’s pressure rating and hose diameter to the tool’s demand prevents pressure loss and uneven performance.

Industrial reels often support up to 300 PSI, while DIY models may handle only 150–250 PSI. The reel’s fittings must also match the air compressor and tool connections to avoid leaks.

Proper compatibility extends equipment life and reduces downtime. A well-matched reel system allows consistent airflow, smooth tool operation, and safer handling during daily use.

Conclusion

Industrial air hose reels differ from DIY models in strength, capacity, and durability. They use heavier materials, stronger springs, and higher pressure ratings to handle constant use in demanding environments. DIY versions suit lighter tasks and smaller spaces where cost and convenience matter more than endurance.

The construction of industrial reels allows them to manage longer hoses and higher air flow without pressure loss. Their sealed bearings and reinforced frames reduce wear and extend service life. In contrast, DIY units often use lighter metals or plastics that meet basic workshop needs but wear faster under strain.

Choosing between the two depends on how often the equipment operates and the pressure levels required. Industrial users gain long-term value from sturdier reels, while hobbyists benefit from simpler, more affordable designs that meet occasional use.

Read Next: Oscillating Tool: The Ultimate DIY Powerhouse for Home Projects